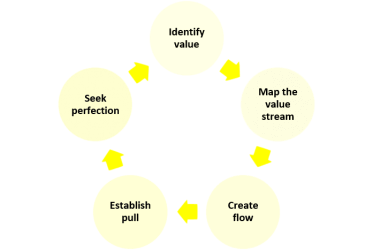

Womack and Jones formalized LEAN and popularized it with the book “Lean Thinking”. They set out 5 principles:

- Set value

- Identify the value stream

- Promote the flow of flows

- Pull streams

- Strive for perfection

Set value

To define value, you have to put yourself on the customer’s side and ask yourself the question?

For what I am willing to pay?

The customer is not prepared to pay to compensate for the waste and inefficiency of the supplier.

Identify the value stream

This means identifying the value-added operations used to develop the product or service as expected by the customer.

But it also means identifying non-value-added operations, i.e. waste.

Creating flow

As with a river, a production flow or an administrative flow will flow more easily in a rectilinear process where operations follow one another without disruption and without interruptions.

Using a pull system

Goods or services should only be produced if the customer has explicitly requested them.

Pursuing perfection

Once the transformation dynamic has been launched, we must enter the cycle of permanent progress in order to bring in new ideas and eliminate new waste.