TOC : Theory Of Constraints

The Theory Of Constraints on the assumption that all processes are unbalanced. It then aims to establish a continuous process based on the control and optimization of the lowest resource, called “constraint”.

Every organization has a goal, which is to make money and, more generally, to create added value. But any organization undergoes a constraint on this target. The Goal is the title of the industrial novel written by Eliyahu Goldratt who popularized the TOC concepts.

The various constraints

A constraint, is a factor that limits the performance of a process. There are different types of constraints.

The knowledge and beliefs

The knowledge and beliefs can be constraints because they structure our thinking and make us define policies and implement rules. If these beliefs are inaccurate, the rules can then become limiting factors.

The knowledge and beliefs can be constraints because they structure our thinking and make us define policies and implement rules. If these beliefs are inaccurate, the rules can then become limiting factors.

- Examples :

- Inaccurate perceptions of customer expectations

- No questioning of a process following the introduction of a new product or a new machine.

The company policy

The company’s policy sets guidelines. Thereof may flow opposite each service policies.

The company’s policy sets guidelines. Thereof may flow opposite each service policies.

- Examples :

- Minimize costs to a minimum: Purchase service = large orders – Production: Large batch size manufacturing – Logistics: Minimum stock -> that is in opposition of the 2 methods of purchasing and production managements.

- Production equipment for making by order : The sales department introduces a narrow range with high volume –> The production organization is inadequate for this type of production

The resources

A constraint resource is an expensive or scarce resource. It can be: A machine, a material, a labor, the market.

A constraint resource is an expensive or scarce resource. It can be: A machine, a material, a labor, the market.

- Examples :

- A machine used at 100% capacity and having no availability.

- A specific raw material, difficult to supply.

- An operation requiring a particular know and few people have mastered before a long training.

- The market can be a constraint if it can not absorb what we produce.

Regulations and Standards

Regulations and standards can limit a system-level volume, time of use, level of use. This can be quotas, schedules, mandatory controls.

Regulations and standards can limit a system-level volume, time of use, level of use. This can be quotas, schedules, mandatory controls.

- Examples :

- Usage quota of a raw material

- Plant closure from 22:00 until 6:00

- Stopping an equipment for control every x hours

- Speed reduction to decrease the noise level

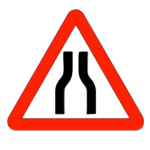

The implementation in 5 steps

The objective of the Theory of Constraints is to identify the constraints and maximize their use. For this, it proposes a 5-step improvement process.

Identify the constraint

Identify the constraint

A constraint necessarily exists, otherwise production would be infinite. The research of the bottleneck, the weakest link is usually fairly simple in production. The bottleneck is generally known. If this is not the case, we must look at the expensive and complex machines, machines to which a large work in process is upstream and for which, downstream resources are pending.

The non-production bottlenecks are more difficult to identify. This can be a stressful job with operator, a standard limiting the flow, waiting to file a service.

Exploit the constraint

Exploit the constraint

The constraint determines the performance of the entire system. So use all its capacity. It will follow the OEE of it and put in place the tools to improve.

Subordinate everything to the constraint

Subordinate everything to the constraint

The flow of the whole process is based on the constraint. You have to use it fully and arrange for that buffer stocks upstream and downstream. Planning should be keyed to this constraint.

We must use the principle DBR : Drum – Buffer – Rope

- Drum : It is the resource that beats the rhythm (pacemaker). All other resources must synchronize to this bottleneck. It is the role of planning and scheduling.

- Buffer : It is the buffer stock that protects the resource against any risk of disruption. A stop on this bottleneck is a loss of revenue for the whole society. The sizing is very important.

- Rope : It is the image of a rope preventing the upstream resources having superior capacity to produce more than the bottleneck can absorb. It is useless to produce in advance.

Elevate the constraint

Elevate the constraint

If after improvements, the capacity constraint is not sufficient, then it is necessary to increase thereof.

- Recruit additional staff

- Invest in additional machine

- Move to a more productive technology

- Use outsourcing

Back to Step 1: Continuous Improvement

Back to Step 1: Continuous Improvement

If the constraint is removed, that she has moved on another bottleneck. We must return to step 1 and repeat.

The 9 rules of Theory of Constraint

To fully utilize the bottlenecks and what to produce, when necessary, the constraints of the theory is based on 9 rules .

Balance flow, not capacity

Balance flow, not capacity

It is impossible, even adapting to balance the capacity of a company. So, we must regulate the flow in order to have a fluid flow. For this, the entire stream is to be mounted on one of the bottleneck.

![]() An hour lost at a bottleneck is an hour lost for the total system

An hour lost at a bottleneck is an hour lost for the total system

By definition, the bottleneck with no reserve capacity, it can not catch up. In return, extract additional capacity on the bottleneck will benefit the entire system.

An hour saved at a non-bottleneck is just a mirage

An hour saved at a non-bottleneck is just a mirage

The resources remain dependent on bottleneck. An hour earned on a non bottleneck, does not benefit the system, but will benefit only stock that will increase.

![]() The level of utilization of a non-bottleneck is determined not by its own potential but by some other constraint in the system

The level of utilization of a non-bottleneck is determined not by its own potential but by some other constraint in the system

By applying the principle of the DBR, non bottlenecks resources must be keyed onto the bottleneck. Using non-bottlenecks according to their capacity, would only produce excessive stocks.

Utilization and activation of a resource are not the same

Utilization and activation of a resource are not the same

A resource must be enabled to use 100% but at the needs of the bottleneck.

Bottlenecks govern both the throughput and inventory in the system

Bottlenecks govern both the throughput and inventory in the system

The overall throughput of the system can not exceed the amount of the constraint. The blind activation of upstream resources can quickly inflate inventories.

The transfer batch may not and often should not be equal to the process batch

The transfer batch may not and often should not be equal to the process batch

A transfer batch lower then a process batch allows to bind the parallel production of many resources, but also to forward the package more quickly to the next resource and therefore accelerate the flow.

The process batch should be variable, not fixed

The process batch should be variable, not fixed

Size Stationary batches impair the flexibility and responsiveness. The production were rarely regular (seasonal), variation in batch sizes is interesting to better monitor demand.

Capacity and priority should be considered simultaneously, not sequentially

Capacity and priority should be considered simultaneously, not sequentially

The planning and scheduling are based exclusively on the bottleneck. It must always work. We must therefore ensure that capacity but also rawmaterial availability are consistent on the upstream positions.

Indicators and management ratios

Theory of Constraints identifies three indicators :

- Throughput : The flow of sales

- Inventory : Committed money

- Opérating expenses : Expenses for transforming Throughput in Inventory

T : Throughput

The rate at which customer sales are generated less truly variable costs (typically raw materials, sales commissions, and freight). Labor is not considered a truly variable cost unless pay is 100% tied to pieces produced.

I : Inventory

Money that is tied up in physical things: product inventory, machinery and equipment, real estate, etc. Formerly referred to in TOC as Inventory.

OE : Opérating Expenses

Money spent to create throughput, other than truly variable costs (e.g. payroll, utilities, taxes, etc.). The cost of maintaining a given level of capacity.

These indicators define the following ratios :

- NP (Net Profit) = T (Throughput) – OE (Operating Expenses)

- ROI (Return On Investment) = NP (Net Profit) / I (Inventory)

- P (Productivité= = T (Throughput) / OE (Operating Expenses)

- CF (Cash Flow) = T (Throughput) – OE (Opérative Expenses) – I (Inventory)

The Theory of Constraints incentive to increase the turnover to improve profitability rather than focusing on cost reduction. It also grows to reduce stocks to reduce cash requirements.

The motto of the Theory Of Constraints

The global optimum is not equal to the sum of local optima.

A local improvement does not necessarily bring an overall improvement

A local improvement does not necessarily bring an overall improvement