TAKT – Balancing line

For a furniture manufacturer, it is important to dimension the assembly line (or in the case of flat-pack packaging) to properly integrate the concepts of Takt Time and line balancing.

It is based on these results it may :

- Size the resources (material and labor)

- Identify bottlenecks

- Balance and adjust the number of workstation

- Adjust the daily capacity

Takt Time

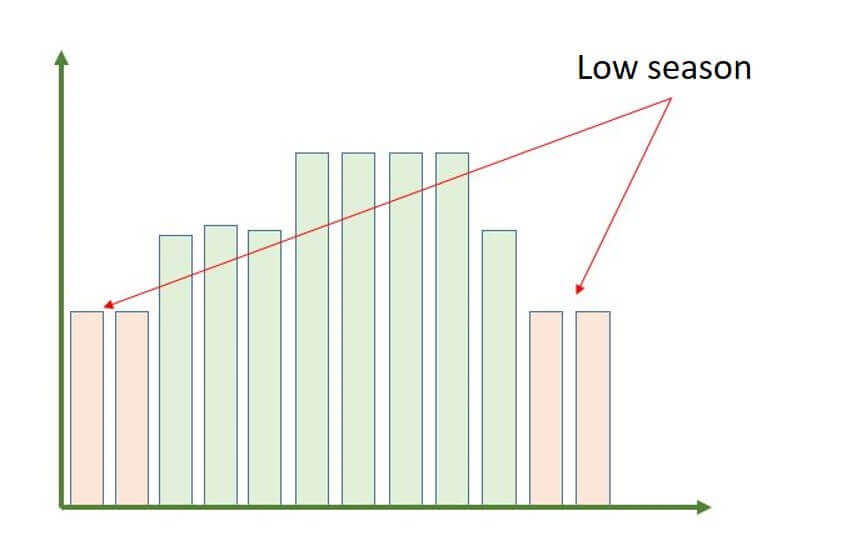

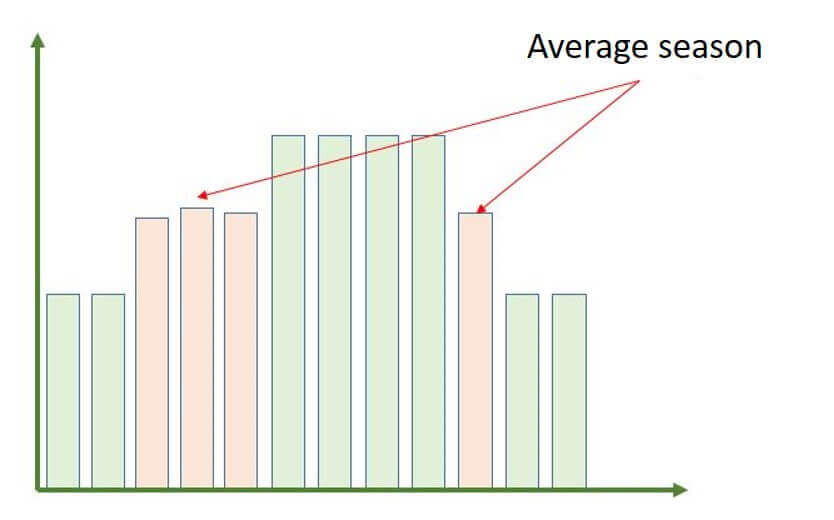

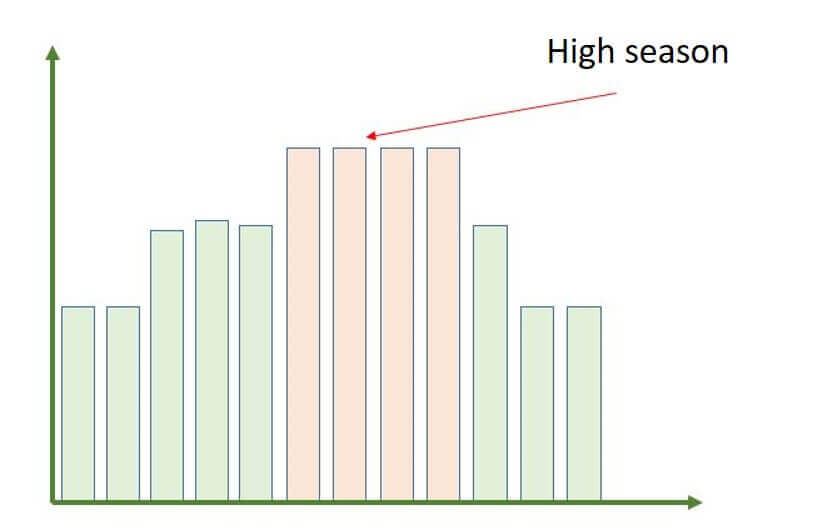

Take the example of a furniture maker, working to order and is subjected to three levels of seasonality during the year (+/- 30%).

- Low season : 1890 furnitures / month

- Average season : 2520 furnitures / month

- High season : 3150 furniture / month

The assembly line work 21 days per month, and eight hours a day. During the day, a break of 20 minutes is performed. Finally, the OEE of the line is 85%.

As explained in the chapter on Takt Time, it is calculated as follows :

Takt = Working Time / Number of Units

We must calculate a Takt Time by season, 3 Takt Time.

[/fusion_imageframe][/fusion_builder_column]Takt low season : 21 x ((8 x 60) – 20) x 0.85 / 1890

[/fusion_imageframe][/fusion_builder_column]Takt low season : 21 x ((8 x 60) – 20) x 0.85 / 1890

Takt = 4.34 mn so 4mn 20s

[/fusion_imageframe][/fusion_builder_column][fusion_builder_column Takt average season : 21 x ((8 x 60) – 20) x 0.85 / 2520

[/fusion_imageframe][/fusion_builder_column][fusion_builder_column Takt average season : 21 x ((8 x 60) – 20) x 0.85 / 2520

Takt = 3.26 mn so 3mn 15s

[/fusion_imageframe][/fusion_builder_column][fusion_builder_column Takt high season : 21 x ((8 x 60) – 20) x 0.85 / 3150

[/fusion_imageframe][/fusion_builder_column][fusion_builder_column Takt high season : 21 x ((8 x 60) – 20) x 0.85 / 3150

Takt = 2.61 mn so 2mn 36s

Size the resources – Identifying the bottlenecks

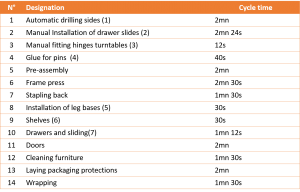

The various positions on the assembly line and their cycle times are :

- Average drilling time per side is 1 minute.

- The average time screwing is 2 minutes per side and 60% on furniture.

- The average time hinge plates is 30 seconds by furniture and furniture 40%.

- The average time for the glue for the pins is 20 seconds per side.

- The average time for the feet bases is 45 seconds per unit and 65% on the furniture.

- The average time for the shelves is 1 minute and 50% on furniture.

- The average time for the drawers and sliding is 2 minutes and 60% of furniture.

The leading position is the framing station. 2 minutes 30 seconds time are a technological time that can not be reduced. Whatever seasonality, the position is not bottleneck. Its Cycle Time is close to Takt Time (2mn 36s vs 2mn 30s), it should be ensured to feed it regularly. A work in process of 2 or 3 furniture can be useful between the pre-assembly and this post. We must also ensure that the evacuation will be done regularly and in this case also, a work in process of 1 or 2 furniture can be interesting.

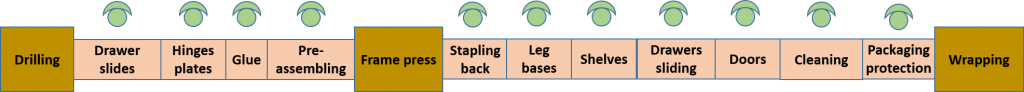

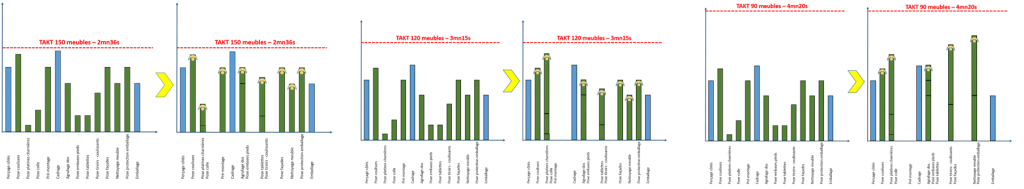

Balance and adjust the number of posts

Depending on the Cycle Time and different Takt Time, we will be able to balance and adjust the number of operators on manual stations. There is 11 positions.

The overall cycle time for all of these positions is 868 seconds.

The theoretical calculation of the number of operators for the different takt time is as follows :

- High season : Takt = 2mn 36s soit 156s —> 868 / 156 = 5.5 so 6 operators

- Average season : Takt = 3mn 15s soit 195s —> 868 / 195 = 4.5 so 5 operators

- Low season : Takt = 4mn 20s soit 260s —> 868 / 260 = 3.3 so 4 operators

The assembly line is linear, and a length of at least 40m, balancing can be done only on contiguous positions. It is thus not possible to use the theoretical calculation.

The various balances are the following :

The number of operators, according to seasonality is from 8 to 5.

Adjust daily capacity

Depending on the working time, breaks and OEE, the operating time of the line is 391mn.

The leading cycle time is 2mn 30s, the maximum capacity of the line is :

391/150 —> 156 furniture

The different ways to overcome superior demand are :

- Perform additional hours (1 hour = 24 Furniture)

- Extend the delivery time in high season and reduce it in average and low season (load and capacity)

- If the additional volume is important and durable, set up a 2nd team.

Download tool sheets about Takt Time and Cycle Time