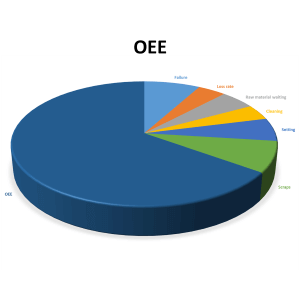

OEE (Overall Equipment Effectiveness) is a results indicator and an operational indicator.

|

Results indicator

|

|

Operational indicator

|

![]()

Should we measure permanently or only on demand : results or operational, it is clear that this must be done permanently.

The time records.

But tracking the OEE requires time records. These records can be done manually or automatically.

|

Manually record |

|

This is the easiest and fastest way to implement. It is also a very didactic method for operators, which are made quickly aware of the different sources of loss.

To do this, operators perform records sheets, which have been formatted to facilitate filling. These sheets are then entered into a computer tool to exploit: OEE calculation, archiving and classification of causes of stops. This software tool is very often based on Excel.

This rapid method to implement, inexpensive is against consuming for operators. It does not allow monitoring of real-time production. Returns are daily, weekly or monthly.

| Automatically record |  |

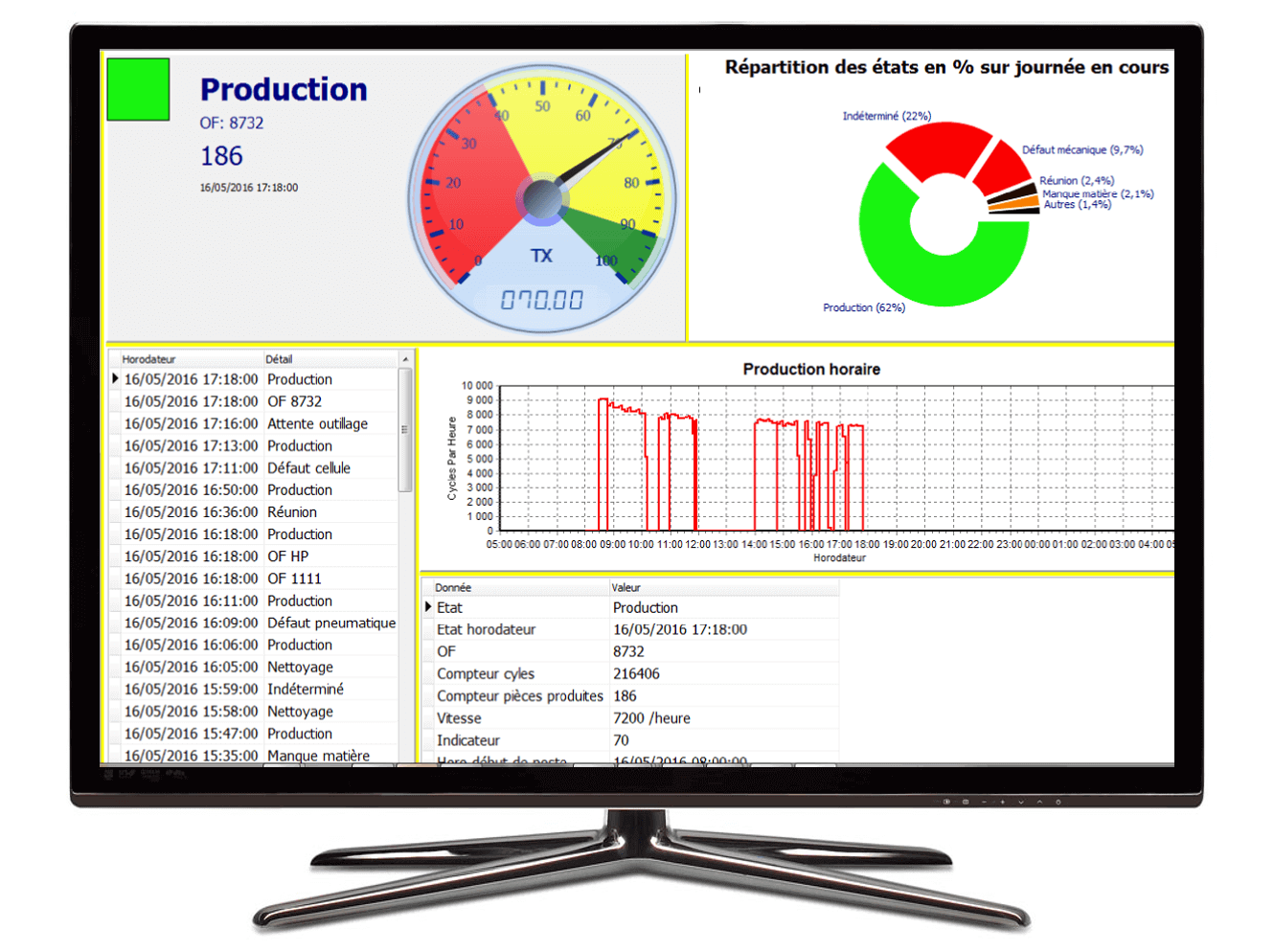

Automatic records are using workshop terminals that can be equipped with a keyboard, a bar code reader or a touch screen. The operators inform the causes of stops, the shared database then being informed in real time.

The most successful systems detect automatically the starting and stopping of the machine, and they account manufactured parts. A warning message is displayed on the terminal, and the operator only has to grasp the cause of the shutdown. The various causes, the theoretical speeds are entered beforehand in the database.

All the time and quantities are recorded automatically and in real time. The OEE, the distribution of causes of stops are calculated continuously.

This method provides better comfort and improved reliability compared to manual records. The data obtained are more accurate : micro stops are listed for example, when they are often hidden in the case of manual input. This method, as with the manual records requires rigor from the operators.

A preliminary study and an investment in equipment and software is required. But if the preliminary study is well done, the return on investment is very fast.

In real time: OEE – Status distribution – Rate

Manually record or automatically record?

Manually record |

Automatically record |

|

|

|

|

|

|

|

|

Starting an OEE measurement approach can be done manually. This will allow train operators. But the overall development requires automatic records.