Nesting

Nesting is a sawing-machining system in one operation. It is suitable for panels based furniture manufacturers, working to order with low to medium production volumes.

The Nesting is widely used in North America, much less in Europe. The format of the panels and the assembly system by dowels are surely one of the obstacles to its development in Europe.

This technology, which is linked with an organization of specific flows, replaces the traditional system, which included at the begining of the process a panel saw.

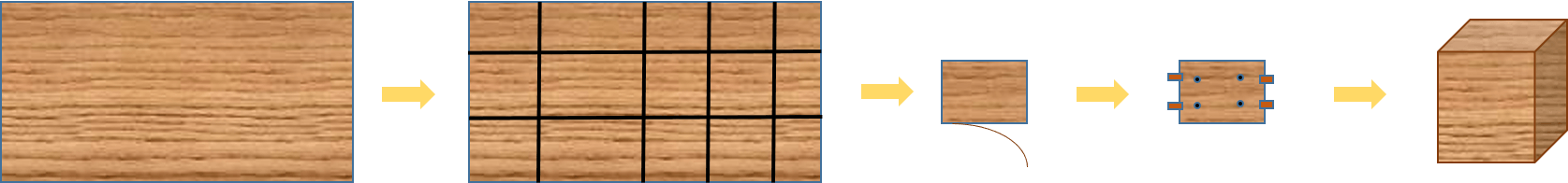

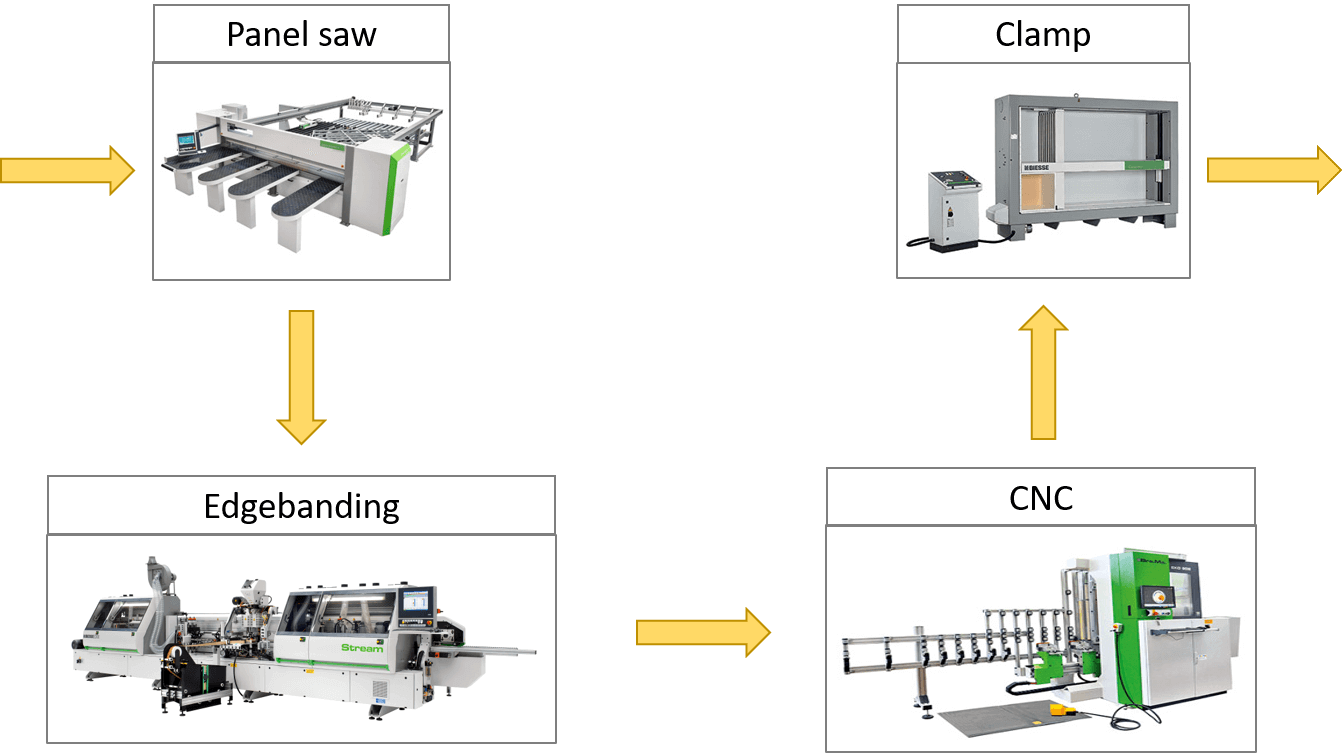

General organization with panel saw

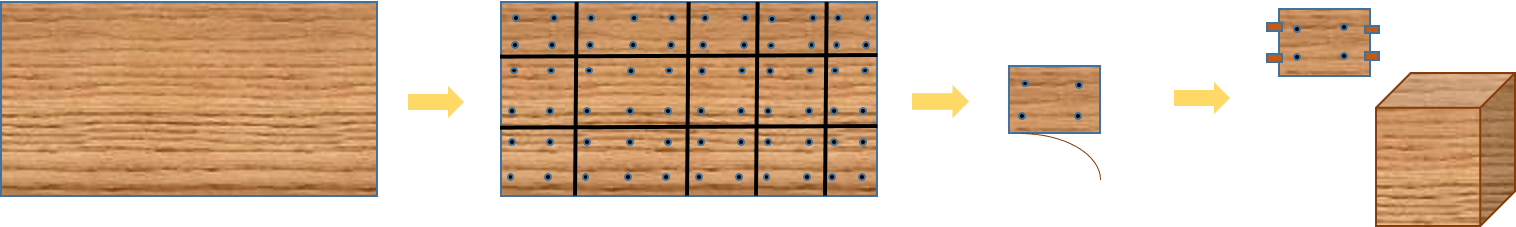

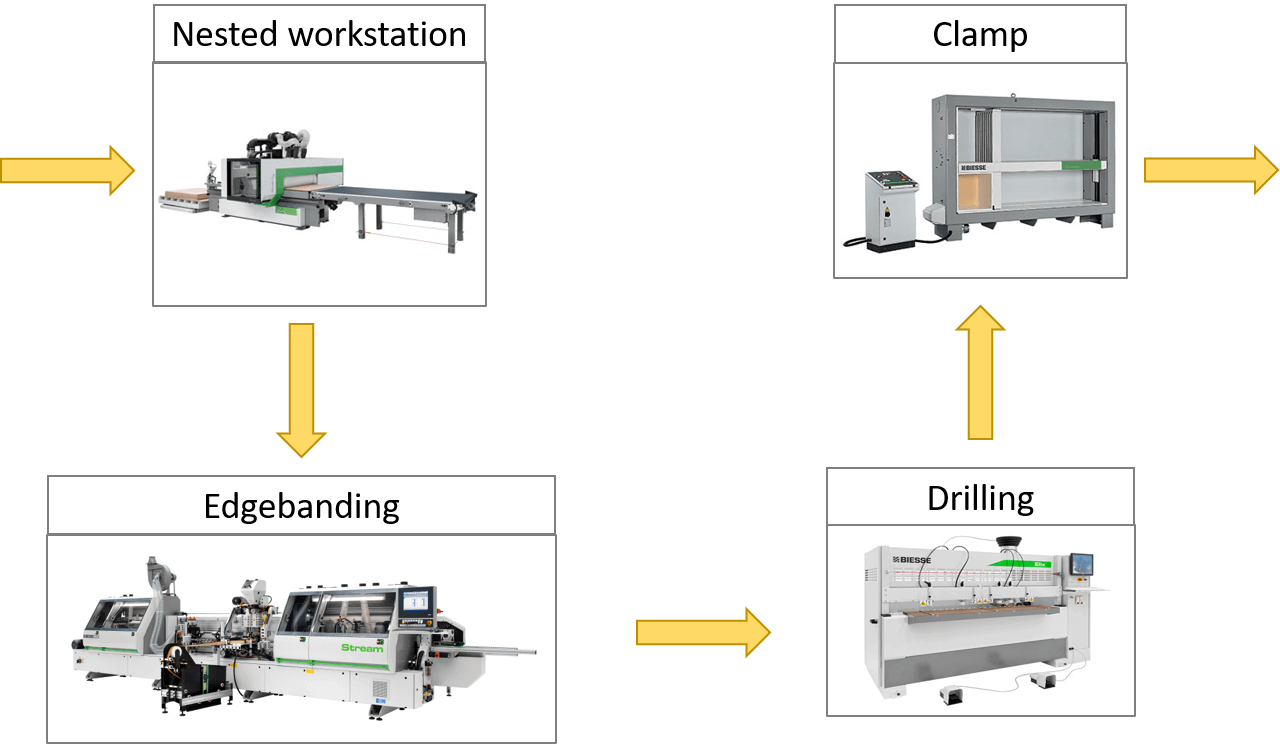

General organization with CNC Nesting

Nesting center

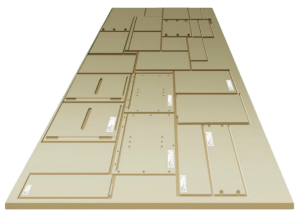

A Nesting center is CNC machining for performing all these operations :

- Sawing

- Drilling

- Grooving

- Routing

It will allow to achieve simultaneously, the complete machining of all the components of an order. This combination of operations will therefore help to bring these gains:

- Reduction of the number of operators

- Reduction of the necessary floor area

- Reduction of the number of manipulations

- Reduction of the work in process

- Reduction of the Lead Time

- Reduction of the need for investment

The Nesting seem therefore have only benefits. It should nevertheless be noted the following 3 issues that are hindering the development of this system :

- Drilling for the dowels, or any other type of assembly requiring horizontal drilling.

- Production volume: a center for Nesting integrating all operations can not make more than 10 panels per hour, limiting production to furniture 175/200 maximum per team.

- Panel sizes: Standard Nesting centers are often limited in width panels.

The criteria to be considered

Before any choice for the establishment of a production line with a Nesting center , you must consider the following poins :

- Production volume: What is your production volume per team and translate the volume in panels quantity. You must integrate the fact that a Nesting center will not make more than 10 panels per hour on average. If the volume is higher, you can opt for the establishment of several centers, or else implement a solution with panel saw.

- Sizes of the raw material: You need to ensure the maximum sizes of the panels that you supply. The centers are often limited in width panels.

- Panels loading: You can choose between an automatic loading (in this case you will not stop between 2 panels machining) or manual loading (only if your production volume is very low). If you opt for an automated loading, know that you can connect it to an automated store panels with dynamic stock management. You will gain more floor space.

- Nesting software: You have an important choice of software. You can take the machine manufacturer’s software, or a software from a separate company. The Nesting software must be interfaced with your design software and it must control the Nesting center. The software should be able to control a printer allowing you to create tags for all the pieces at the output of the machine.

- Trolleys: You must fully examine your need for trolleys for transfers between the Nesting center and the edgebanding and between the endgebanding and the assembly line : dimensions and partitioning, quantity.

Equipment suppliers

Equipment suppliers that are listed, realized Nesting center but can also integrate handling, edgebanding, drilling and assembling.

![]()

BIESSE group.

HOMAG group.

IMA group.

IMA group.

SCM group.

Conclusion

The Nesting is a very good solution when you want to make furniture by order with a low to medium production level. This will allow you with less investment, operators and surface, to work just in time and thus reduce your work in process and your Lead Time.

This method will improve your service rate.