OEE

OEE (Overall Equipment Rate) is the most widely used indicator in the context of a LEAN approach. Following the detailed activity of a workstation, it allows us to separate the time with value added from the time with non value added.

It allows to identify waste, classifying them in order to plan actions for improvement.

The composition of OEE

OEE measures the performance of an equipment depending on 3 components:

The availability of equipment

The availability of equipment

Ar = (Planned production time- stop loss) / Planned production time

The equipment performance

The equipment performance

Pr = (Theoretical cycle time x total amount of parts) / Performing time

The quality provided by the equipment

The quality provided by the equipment

Qr = (Parts total amount – scraps amount) / Parts total amount

OEE = Ar x Pr x Qr

Example :

- Equipment has a 7:00 planned production time.

- The recorded stops (failure, setting, material supply, …) are 40 minute.

- The theoretical cycle time is 125 pieces / hour, but the actual time is 110 pieces / hour.

- The total amount of manufactured parts is 695. Of the total, 45 pieces are rejects.

- Ar = (420 – 40) / 420 = 90.5%

- Pr = (695 x 60 / 125 ) / 380 = 87.8%

- Qr = (695 – 45) / 695 = 93.5%

OEE = 90.5% x 87.8% x 93.5% = 74.3%

The OEE is a severe indicator. As soon as a rate is falling, the OEE is strongly impacted.

Performance losses

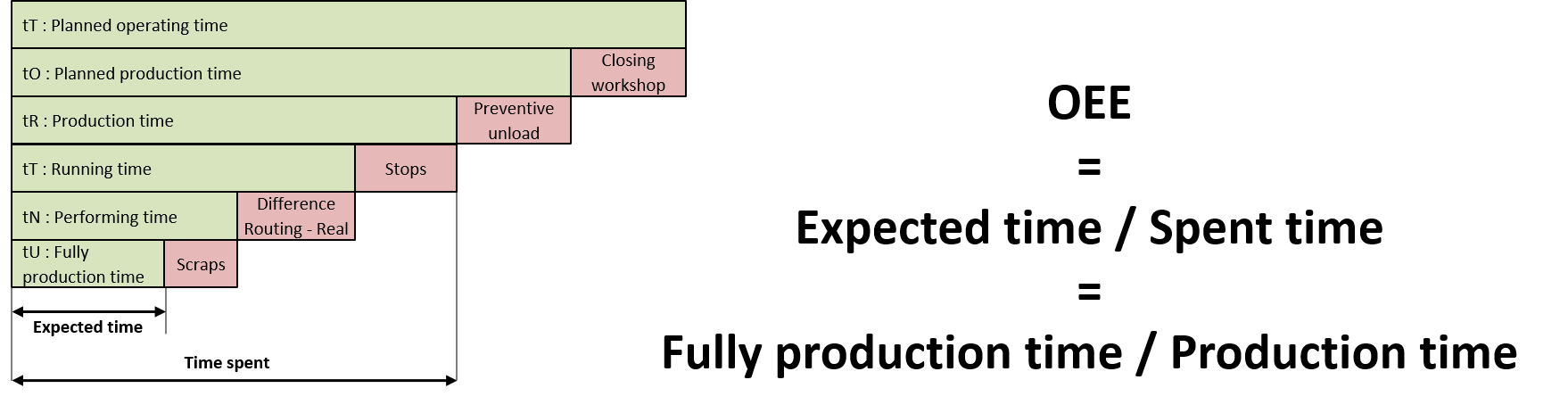

Different time :

| tT | Planned operating time | Total time of the measurement period |

| tO | Planned production time | Possible time of equipment utilization |

| tR | Production time | Schedule operating time |

| tF | Running time | Net operating time |

| tN | Performing time | Routing time allocated to the entire output produced |

| tU | Fully production time | Routing time allocated at the sold production |

6 sources of loss:

Performance losses can be classified into 6 sources.

- Failures: This is all the losses related to equipment failure (electrical, mechanical, automation, …)

- Organisation: Organizational defects are the cause of many performance losses. These may be: lack of staff, lack of material, waiting information, waiting removal of the finished products, …

- Micro stops: These are the short stoppages difficult to quantified. This is often a cause of significant performance loss. They are found in the rate of loss.

- Slowdown and under speed: This is the difference between the theoretical rate and the actual rate. This is often a result of wrong settings or an optimistic view of the potential rate of equipment.

- Production start: These are losses related to setting for new production order, the test for new pieces, the starting of a new team …

- Quality problems: These are all scraps and re-manufactured parts.

Why follow OEE

OEE is a multi-purpose indicator :

- Results indicator

- Operational indicator

Its analysis, and especially that of its constituent data leads us to highlight the main causes of under performance. From here, we can analyze and implement improvement actions to solve them.

Improving the OEE, brings us to improve productivity and to provide additional capacity.