The Kanban

Kanban is a Japanese word wich mean label.

Operation

A Kanban system works between 2 positions (upstream and downstream or customer and supplier)

- The customer operator starts a bin. Then he removes the label Kanban and puts it in a box.

- The warehouseman picks the Kanban label and led him to the supplier position

- He places the label on the kanban board

- According to an alert threshold, the supplier decided to produce components

- The supplier puts labels on filled bins

- The warehouseman deliver bins to the client

It is thus automatically controls the production flow and production inventory levels, the position upstream producing only if the downstream station has “consumed” products.

The Kanban loop

The kanban loop is the circuit through the labels of a kanban management system. This circuit is closed, the labels must not get out. A kanban loop is always placed between a custommer and its supplier. There may be two work stations, two blocks, two production lines or two workshops. It is also possible to implement kanban loops in supply relationships between a company and its external suppliers. In this case, there are as many loops to provide that there are suppliers concerned by this management.

Sizing

- Calculating the number of labels

To be effective KANBAN management style is based on a calculated design. The calculation of the number of outstanding labels in the kanban loop for a given article is based on the following parameters:

D = Daily demand

d = total time for one cycle (manufacturing, waiting, transportation, reception)

K = safety factor

C = capacity of a container

N = number of labels

N = D x d x (1+K) / C

The maximum allowed stock is :

Sm = N x C

Example :

A consumption of 2400 pieces per day (8 hours)

The time for one cycle is 2 hours

Safety coefficient is 0.05

The capacity of a container is 50 pièces

C = (2400 X 2/8 x (1+0.05)) / 50 = 12.6 so 13 labels.

Sm = 13 x 50 = 650

Priority management

Often, a workstation products different references. For example it can produce parts A, B, C and D. The main problem in this case is to choose the type of parts to be manufactured first.

For this we use the Kanban board.

Suppose we have the same number of labels to be produced for items A, B, C and D.

The number of Kanban is identical for each reference. It is therefore difficult to define a priority.

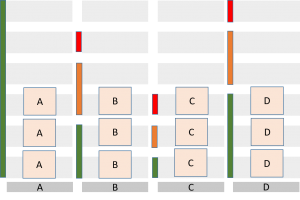

We must know the number of kanban in the loop for each reference. Suppose we have: 10A, 5B, 3C, 6D.

This means we currently have in stock:

10 – 3 = 7A

5 – 3 = 2B

3 – 3 = 0C

6 – 3 = 4D

It is therefore urgent to launch pieces C.

But to prevent the operator performs this calculation every time, we will use a visual board, in the following example.

Red zone: It is urgent to produce

Orange Zone: normal wait time without risk of breaking

Green Zone: This corresponds to the buffer stock – No emergency

Types of Kanban

By definition, Kanban is a label. But there are other types of Kaban that facilitate the management and communication.

Kanban location

The labels are replaced by slots materialized on the ground, geographically located between the supplier and its position or its customers. A slot accommodates a container or box products. The number of locations for each type is determined by the operating system. If one or more locations is or are empty, the supplier must produce. If all slots are full, the supplier must not occur. The number of position corresponds to the number of labels.

Advantages :

- Very visual system, that we either supplier or customer, it is sufficient to take a look at the locations to know where we stand.

- There is no label manipulation; there is therefore no risk of forgetting to return them to the supplier. We do not risk losing them.

Disadvantages :

- The locations are consumed primarily those close to the customer. So there tends to replenish them. As such products are not supported in FIFO

- To overcome this, we must implement storage systems on inclined surfaces, the consumption taking place at the front (bottom) and replenishment at the back (top)

Double bin kanban

In this system, the customer withdraw in the first bin up to exhaustion thereof. The empty bin is then returned to the supplier.

The provider interprets the return of the bin as a supplementary request. He knows that at this point the customer is consuming the second bin. A bin corresponds to the order point.

This method is frequently used for the supplies management (hardware, … )

Warning Label

This method is used eg in pharmacy. The label is positioned in the storage of the products, at the control point.

The consumer consumes the products. When the label becomes apparent, he hands it to the supplier who can provide the command of his client.

Rules

The following rules must be respected so that the system can function over time:

- The supplier manufactures the position quantity of the product specified on the Kanban and no more (nor less).

- No Kanban, should not produce or make product handling.

- You have to have a goal to reduce the quantities of Kanban or reduce the size of the lots which will force us to challenge themselves and improve.

- Do not increase the kanban if out of stock. Search root causes.

- A label is always associated with a product.

- The handler withdraw from the supplier only the number of parts indicated on the Kanban

- The delivered products must have no defects.

Advantages and disadvantages

Advantages :

- Rapid implementation that does not require large financial investments.

- Self-managed method.

- Reduced production time and delivery.

- Visual method.

- Motivation operators.

Disadvantages :

- No anticipation if fluctuation.

- Stop risk of the line in case of defective parts (defects requires 0)

- Does not apply to small series.

- Find suppliers able to keep up with demand.